Explosion-proof heat-actuated spot-type digital fire detector IP-101-GORELTEX1-B is intended for ambient temperature control at places of installation of various technological equipment (pump stations oil and gas pipelines, tank batteries, loading racks, mine workings etc.). Detectors IP-101-GORELTEX1-B perform functions of maximum heat-actuated fire detectors and generate emergency signal when ambient temperature rises above permitted value.

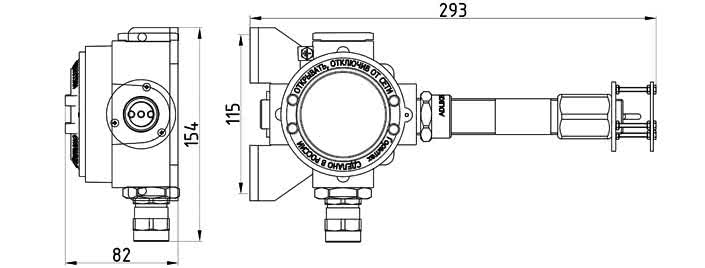

Explosion-proof heat-actuated spot-type digital fire detector IP-101-GORELTEX1-B structurally consists of a thermally-sensitive unit and an explosion-proof terminal box. KKVA box is applied as a terminal box, and terminal box can have 1-2 cable entries. Upon request, the detector can be equipped with a cable/pipe gland for armored cable, corrugated pipe or pipe conduit, a bracket for wall or ceiling mounting, stainless steel chain for cover.

New modification of fire detector IP-101-GORELTEX1 is designed on a base of a microcircuit of digital temperature sensor. Detector‘s operation logic is controlled by a microcontroller. Two relays with changeover contacts are provided, positions of which reflects the state of the fire detector (relay K1 - proper functioning of the sensor and relay K2 - overtemperature). The state of each detector can be additionally controlled usin two light-emitting diodes. If sensor is in good order, green LED is alight. If temperature is equal to or higher than maximum actuation temperature Tmax, overtemperature relay K2 switches and red LED lights up. This state remains until temperature drops below minimum actuation temperature Tmin.

There are two modifications of fire detectors: with power supply from DC source 12-24 V and AC source 230 V 50 Hz.

Full production cycle starting from casting molds and to ready product is performed at the explosion-proof equipment plant “ZAVOD GORELTEX” Co. Ltd. on the territory of the Russian Federation.

- CONTROL OF PROPER OPERATION OF THE DETECTOR

Application of a microcontroller inside the detector allowed us to implement self-diagnostics function. Microcontroller automatically polls temperature sensor, and gives signal of proper operation when it receives an answer.

- ACCURACY OF MEASURED TEMPERATURE

Data exchange between a temperature sensor and a microcontroller is performed as per digital protocol. Accuracy of received data is checked using mechanism of check-sum. Probability of receipt of false data from temperature sensor and, as a consequence, faulty actuation of the detector is reduced to a minimum.

- OPTION OF INTEGRATION WITH FIRE ALARM SYSTEMS OF DIFFERENT MANUFACTURERS

Dry contacts of the relay of proper operation of the sensor and of the overtemperature relay allow integration of address marks of third-party manufacturers and integrate them with fire alarm systems that provide for interaction, in particular with proprietary digital protocols. This option allows for a significant widening of the scope of application of the detectors IP-S-101.

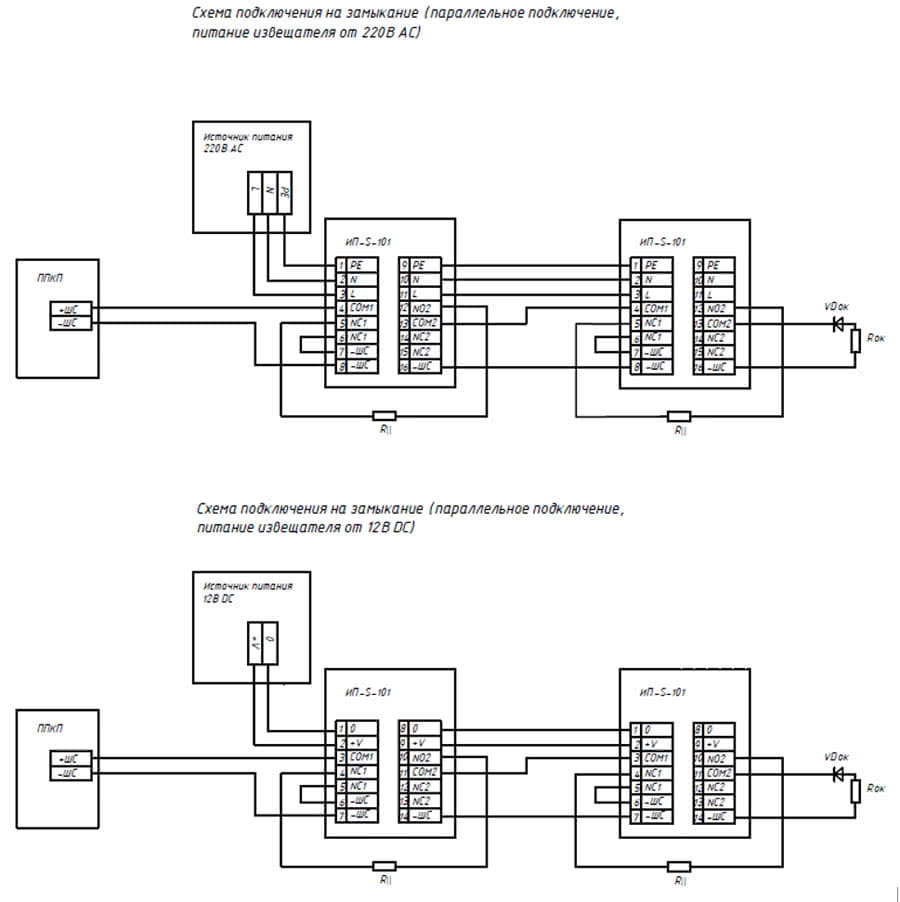

- OPTION OF SERIES OR PARALLEL CIRCUIT

Terminals with contact duplication enable to implement a system with either a series or a parallel circuit of the detector. Additional resistors and connecting conductors are connected to the corresponding terminals (depending on the type of the system) and are located inside explosion-proof terminal box of the detector.

- EXTENDED MONITORING

Apart from a pair of relays with changeover contacts, two light-emitting diodes are provided for visual check of the state of the fire detector (green indicates correct operation of the detector, red indicates overtemperature). Presence of indication makes it possible to quickly determine the source of malfunction when several fire detectors are used in the alarm loop.

Scope of application - underground mines and pits hazardous with gas (methane), coal dust; hazardous indoor and outdoor areas in accordance with explosion protection marking, GOST 30852.13-2002 (IEC 60079-14:1996) and areas hazardous with combustible dust ignition, as per GOST IEC 61241-3-2011, dangerous production facilities of I, II, III, IV hazard classes under supervision of Rostekhnadzor and national supervisory bodies of the CU and the CIS countries.

12…24;

12…24;  12 V)

12 V) 12 V)

12 V)

| IP-101-GORELTEX1-B | - | Х | - | Х | / | Х | – TU 4371-013-72453807-2011 |

| Detector type | |||||||

Operating voltage:  6…24 V - 12DC; ~90...250 V - 220AC 6…24 V - 12DC; ~90...250 V - 220AC |

|||||||

| Dimension type of cable gland (max. 2 pcs.) | |||||||

| Options, accessories and versions |

Example: IP-101-GORELTEX1-B-220AC-KNV1N-TU 4371-013-72453807-2011

| Temperature rise speed, °С/min. | Actuation time, s | |

| minimum | maximum | |

| 1 | 1740 | 2760 |

| 3 | 580 | 960 |

| 5 | 348 | 600 |

| 10 | 174 | 329 |

| 20 | 87 | 192 |

| 30 | 58 | 144 |

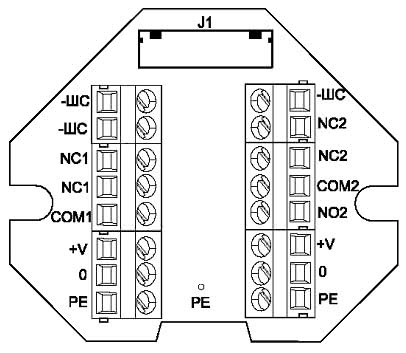

| Contact designation | Purpose | |

| -ШС | Alarm loop (minus) | |

| Relay of proper operation of the sensor K1 | NC1 | Normally closed contact of the relay of proper operation of the sensor. Open (closed) if the sensor is operating properly (faulty) |

| COM1 | Common contact of the relay of proper operation of the sensor | |

| +V | +12…24 V DC | |

| 0 | 0 | |

| PE | Grounding | |

| Thermostat relay K2 | NC2 | Normally closed contact of thermostat relay. Closed if temperature hasn‘t exceeded Tmax. |

| COM2 | Common contact of thermostat relay | |

| NO2 | Normally open contact of thermostat relay. Closed if temperature has exceeded Т max and hasn‘t dropped below T min |

|

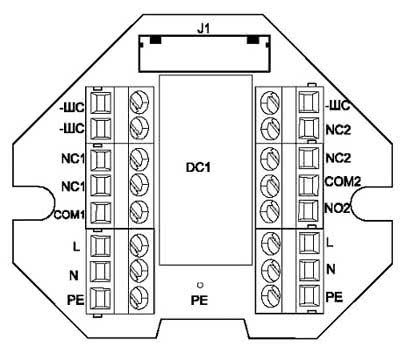

| Contact designation | Purpose | |

| -ШС | Alarm loop (minus) | |

| Relay of proper operation of the sensor K1 | NC1 | Normally closed contact of the relay of proper operation of the sensor. Open (closed) if the sensor is operating properly (faulty). |

| COM1 | Common contact of the relay of proper operation of the sensor | |

| L | Phase 220 V 50 Hz AC | |

| N | Neutral 220 V 50 Hz AC | |

| PE | Grounding | |

| Thermostat relay K2 | NC2 | Normally closed contact of thermostat relay. Closed if temperature hasn‘t exceeded Tmax |

| COM2 | Common contact of thermostat relay | |

| NO2 | Normally open contact of thermostat relay. Closed if temperature has exceeded Т max and hasn‘t dropped below T min | |

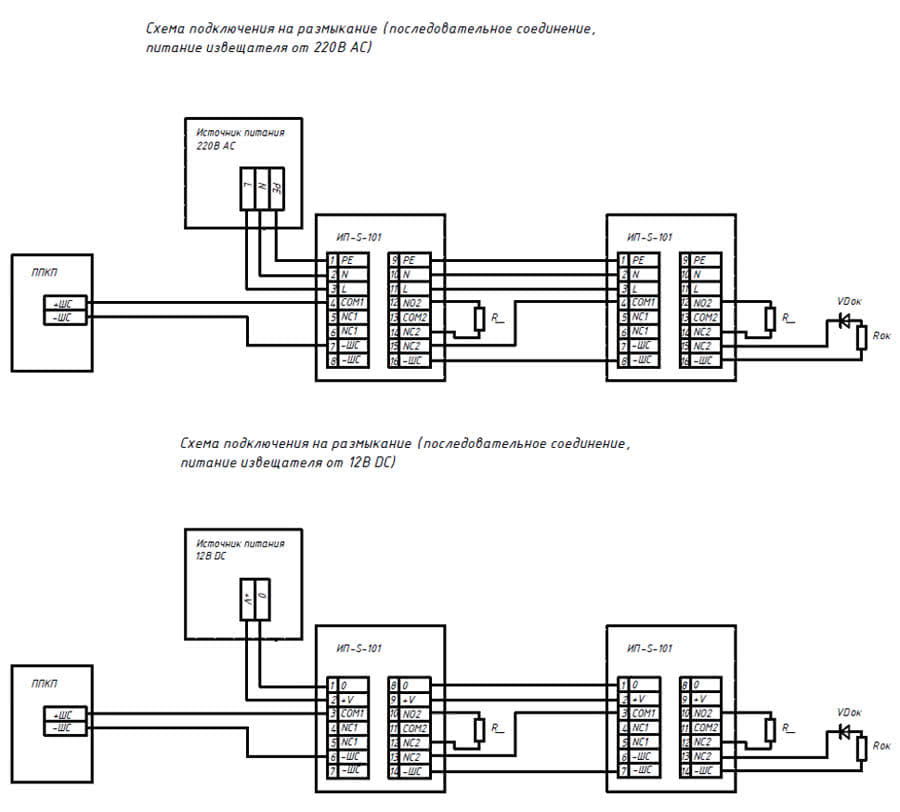

Wiring diagrams of fire detector IP-101-GORELTEX1 to FACU (FIRE ALARM CONTROL UNIT)

Elements shown on the diagram are arranged in the explosion-proof terminal box of the fire detector. The ratings are selected depending on the type of applied fire alarm control unit. The ratings of the elements for the most widespread types of FACU are shown in the table:

| Type of FACU | Parameters of the connection | |

| Parallel circuit (closing) | Series circuit (opening) | |

| LB-07 | Rd shall ensure current consumption >15 mA, |

Rd = 11 kΩ, |

| Luch | Rd = 2.4 kΩ, |

Rd = 2.2 kΩ, |

| PPK-2 | Rd = 1.2 kΩ, |

Rd = 10.0 kΩ, |

| Bolid | Rd = 1.5 kΩ (3.0 kΩ - to determine dual actuation), Rok = 4.7 kΩ, jumpers instead of VDok |

Rd = 8.2 kΩ (4.7 kΩ - to determine dual actuation), |

| Yakhont-16i | Rd = 1.8 kΩ (4.0 kΩ - to determine dual actuation), |

Not applied |

| VERS | Rd = 820 Ω (1.8 kΩ - to determine dual actuation), |

Rd = 10 kΩ (4.7 kΩ - to determine dual actuation), |