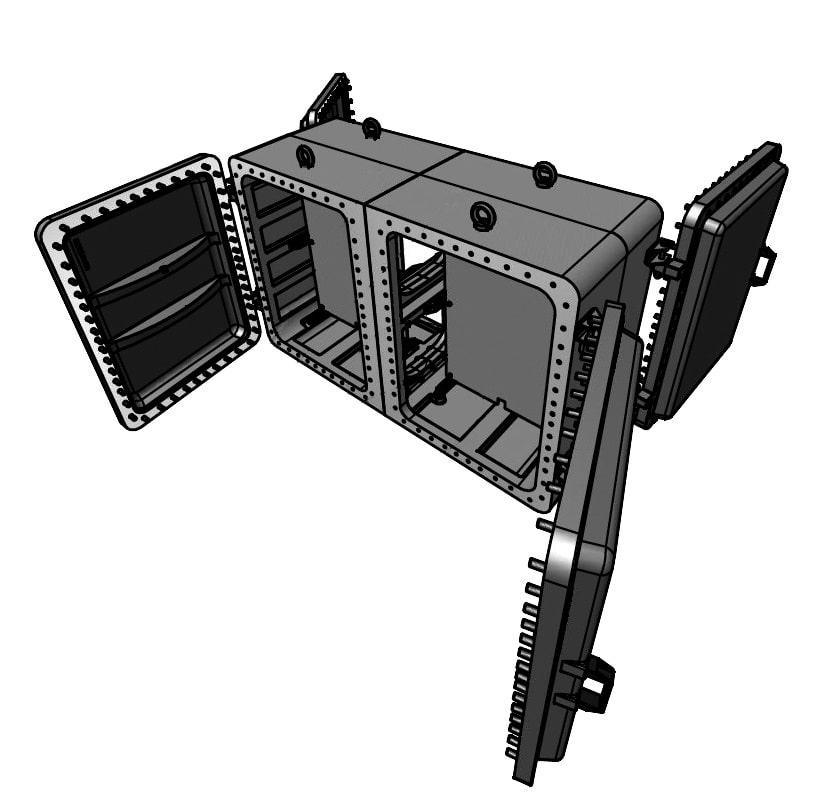

HALK enclosure (SHORV8914068) is intended for safe operation of large-sized equipment, electrotechnical apparatuses and components in hazardous areas. The enclosure provides “Ex d” type of explosion protection and has a long service life. At the design stage, the enclosure undergoes the mathematic modeling and testing in order to confirm the compliance with the stated explosion protection marking.

The enclosure is installed on /RAMA frame for floor mounting made from galvanized steel (cold or hot galvanizing), stainless steel is upon request. The frame is frictionally intrinsically safe non-electrical equipment with IIGb and IIIDb level of protection.

| Dimensions, mm | 1490x774x1850 |

| Mass, kg | 477(without frame), 573(with frame) |

| Access | dual |

| Dimensions, mm | 5000x500x2500 |

| Mass, kg | 1087(without frame), 1255(with frame) |

| Access | single |

Full production cycle starting from the design, casting molds and assembly of finished products is performed at the explosion-proof equipment plant “ZAVOD GORELTEX” Co. Ltd. in the territory of the Russian Federation.

The “X” sign placed after Ex-marking indicates that it is prohibited to use this equipment in hazardous mixtures of acetylene and air.

Scope of application - hazardous indoor and outdoor areas in accordance with explosion protection marking, GOST 30852.13-2002 (IEC 60079-14:1996) and areas hazardous with combustible dust ignition, as per GOST IEC 61241-3-2011, dangerous production facilities of I, II, III, IV hazard classes under supervision of Rostekhnadzor and national supervisory bodies of the CU and the CIS countries.

HALK is the registered trademark in the territory of the Russian Federation.

1Ex db IIB+H2 T6...T4 Gb

1Ex db IIB+H2 T6...T4 Gb 1Ex db IIC T6...T4 Gb X

1Ex db IIC T6...T4 Gb X 1Ex db [ia Ga] IIB+H2 T6...T4 Gb

1Ex db [ia Ga] IIB+H2 T6...T4 Gb 1Ex db [ia Ga] IIC T6...T4 Gb X

1Ex db [ia Ga] IIC T6...T4 Gb X 1Ex db [ib] IIB+H2 T6...T4 Gb

1Ex db [ib] IIB+H2 T6...T4 Gb 1Ex db [ib] IIC T6...T4 Gb X

1Ex db [ib] IIC T6...T4 Gb X Ex tb IIIC T70°...T135°С Db

Ex tb IIIC T70°...T135°С Db Ex db IIB Gb U

Ex db IIB Gb U Ex db IIB+H2 Gb U

Ex db IIB+H2 Gb U Ex db IIC Gb U*

Ex db IIC Gb U* Ex tb IIIC Db U

Ex tb IIIC Db U ЕАЭС RU C-RU.АД07.В.01847/20

ЕАЭС RU C-RU.АД07.В.01847/20 ЕАЭС RU C-RU.НА67.В.00157/20

ЕАЭС RU C-RU.НА67.В.00157/20 ЕАЭС RU C-RU.AA87.В.01061/22

ЕАЭС RU C-RU.AA87.В.01061/22 ЕАЭС RU C-RU.МЛ02.В.00313/21

ЕАЭС RU C-RU.МЛ02.В.00313/21 РОСС RU С-RU.МЮ62.В.00094/23

РОСС RU С-RU.МЮ62.В.00094/23 ГОСТ Р ИСО 9001-2015 (ISO 9001:2015)

ГОСТ Р ИСО 9001-2015 (ISO 9001:2015) РОСС RU.04ПТК0.К00129

РОСС RU.04ПТК0.К00129 RU.OC ВССТ 0179-10.2023

RU.OC ВССТ 0179-10.2023 Морской регистр СТО №22.05089.120

Морской регистр СТО №22.05089.120 ТУ 3400-005-72453807-07

ТУ 3400-005-72453807-07 ТУ 27.33.13-033-72453807-2017

ТУ 27.33.13-033-72453807-2017 ТУ 27.12.40-032-72453807-2017

ТУ 27.12.40-032-72453807-2017 ОГН4.RU.1104.В02600

ОГН4.RU.1104.В02600 KZ39VEH00005608

KZ39VEH00005608Remark: For options /SHINA Z and /SHINA N, bus bars with 2 holes x 16 mm2 and a row of holes 6 mm2 are installed by default (the quantity depends on the bus bar length). Installation of bus bars with different diameter of holes is possible upon customer’s approval.

| Box dimension type | Dimensions, mm | Mass, kg | |||||||||||

| Outer | Inner | Fastening | |||||||||||

| A | B | C | a | b | c | d | e | s | f | g | h | ||

| SHORV8914068 | 896 | 1403 | 684 | 777 | 1284 | 634 | 297 | 365 | 23 | 325 | 727 | M20 | 440 |

IT IS IMPORTANT TO KNOW

IT IS IMPORTANT TO KNOW

Requirements to fasteners of flameproof enclosure as per GOST IEC 60079-1-2013:

§ 11.1 Fasteners accessible inside and outside and required for assembly of parts of the flameproof enclosure shall:

- be special fasteners (countersunk or used in blind holes, or the protection of which is provided by the equipment design) and meet the requirements of GOST 31610.0 (for the equipment of group I);

- be special fasteners and meet the requirements of GOST31610.0 (for the equipment of group II).

Note – Application of countersunk fasteners or in blind holes for the equipment of group I is required for the protection of fasteners heads from impact. Cylindrical heads of screws with hexagonal socket for the equipment of group II shall be countersunk or used in blind holes, or their protection shall be provided by the equipment design.

MECHANICAL PROCESSING OF SHORV BOXES

The thickness of wall and cover of SHORV explosion-proof enclosures is sufficient to manufacture threaded holes for the connection of various types of explosion-proof cable glands, control and indicating elements. There is a wide range of standard control, indicating, and signaling elements, elements and modules for specific tasks, as well as typical elements upon customer’s request. Big size of control elements of M series enables the operators to work in gloves, indicating elements have large diameter – 40 mm and are equipped with a reflector, which makes the signal clearly visible at large viewing angle and various degree of surface dirtiness. Operating handles for circuit breakers are selected depending on the number of poles and circuit breaker type. Handle’s axle length can be adapted to the type of circuit breaker and size and type of the explosion-proof enclosure.

The thickness of wall and cover of SHORV explosion-proof enclosures is sufficient to manufacture threaded holes for the connection of various types of explosion-proof cable glands, control and indicating elements. There is a wide range of standard control, indicating, and signaling elements, elements and modules for specific tasks, as well as typical elements upon customer’s request. Big size of control elements of M series enables the operators to work in gloves, indicating elements have large diameter – 40 mm and are equipped with a reflector, which makes the signal clearly visible at large viewing angle and various degree of surface dirtiness. Operating handles for circuit breakers are selected depending on the number of poles and circuit breaker type. Handle’s axle length can be adapted to the type of circuit breaker and size and type of the explosion-proof enclosure.

| Type | Control and indicating elements, pcs. | |

| Operating handles of the circuit breaker |

Control buttons and signal lamps |

|

| 1 enclosure door | 30 | 87 |